-

+86-18981112257 -

market1@prochema.cn

| Business Type | Manufacturer |

| Shielding Layer | 125±0.05um |

| Adhesive Layer | 25UM |

| Protective Film | 70UM |

| Click to view more | |

Preferred Buyer From

| Location | All Countries |

Product Details

PRODUCT INTRODUCTION

1、Physical Parameter

WSLDM85B electromagnetic shielding film is produced by silk screen and laminated technology. It has high shielding efficiency and light transmittance. It can be easily applied to existing display screens and touch screens. The special structure treatment and scratch resistance function meet the shielding requirements of construction projects. Highly transparent and undistorted visual enable it is preferred material for window shielding. Thicker wire diameters are reserved on both sides of the film during the production process to facilitate grounding treatment.

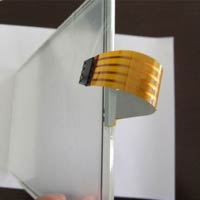

2、Product Structure Diagram

WSLDM85B shielding film improves the structure of the film. The alloy wire mesh is layered between high transparent polyester film and pressure sensitive adhesive. The polyester film is strengthened to achieve 3H anti scratch, which has a good effect on protection for the intermediate alloy wire mesh, resist external hard objects scratch.

1、Shielding Effectiveness

Principle:As an electromagnetic shielding product for EMI/RFI, the core function of WSLDM85B is that it contains a continuous dense alloy grid inside, which ensure excellent shielding effectiveness.

Testing Basis:GJB6190-2008 Shielding effectiveness of EMI shielding materials

Measuring Instrument:Signal generator AV1464B

Spectrum Analyzer E4407B

2、Internal Resistance Test Method

Put the shielding film on a dedicated internal resistance test module for testing.

Measuring Instrument:Square resistance tester

Square Resistance Tester Model:DMR-1C

Data:0.07Ω

The lower the resistance, the better the conductivity of the shielding film and the higher the shielding performance.

4、Acid And Alkali Resistance

Acid-base test: prepare 2N hydrochloric acid, 10% sodium hydroxide, 10% sulfuric acid solution etc.

Sample preparation: pressing and curing the shielding film

Soak cross-cut test:Soak the sample in the solution for ultrasonic cleaning at room temperature for 10 minutes. After taking out the sample to dry, observe whether the appearance of the surface is discolored, and use 3M tape to do cross cut test.

WSLDM85B test result:All qualified.

5、Salt Spray Resistance

Salt spray test conditions:Salt spray test chamber, 5% sodium chloride aqueous solution, temperature 35℃, 72 hours.

Sample preparation:Shielding film 100*65mm.

Evaluation items:Surface corrosion rate.

Result: salt spray corrosion rate is 0%, the result is qualified.

High Temperature And Humidity Resistance

High temperature and humidity test conditions: constant temperature and humidity test box, constant temperature 65℃, constant humidity 90%RH, 7 days (requires drying 120℃*3

Hour, or 160℃*1 hour.)

Sample preparation: Shielding film pressing and curing (Shielding film internal resistance test module 10*30mm)

Evaluation item: shielding performance (resistance change)

Result: After high temperature and high humidity, the resistance of the shielding film changes less than 1%, and the result is qualified.